Cupro Nickel 70/30

70/30 Cupro Nickel is very widely employed in water desalination plants, especially in the most critical areas such as the heat reject and brine heater stages, as well as in the under cooling areas of power station condensers, in the chemical, petrochemical and food processing industries and, more generally, in all applications where top corrosion resistance is required from both the shell and tube side.

PRODUCT APPLICATION AREAS

SIZE |

1/2" to 6' in OD & NB in various SWG & SCH |

FORM |

Round, square, rectangular, coil, ‘u’ shape, pan cake, hydraulic |

LENGTH |

Single random, double random & required length |

END |

Plain end, beveled end, threaded |

MATERIALS |

Copper nickel – Cu-Ni Seamless Tube, C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30) |

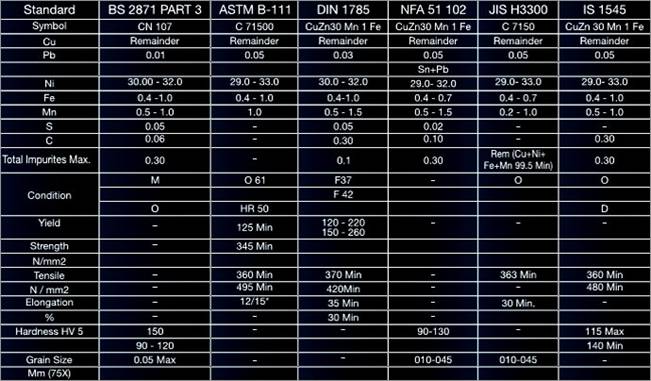

Technical Specification

.jpg)